WHAT IS INDUCTION HEATING

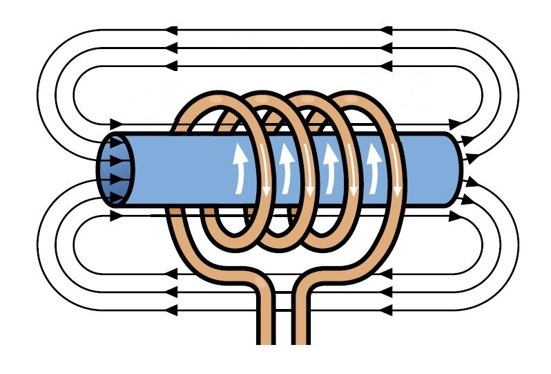

Whenever the high or medium frequency alternating electric current changes direction, the generated magnetic field change direction in turn.

When an electrically conducting component is inserted into the magnetic field it absorbs the energy as alternating electric current.

As in a transformer, the inducted current in the workpiece (secondary circuit) is proportional to the current circulating in the heating coil (primary circuit) and inverse to the square of their distance.

The inducted electric current, also called parasitic current or eddy current, generates heat on the surface of the component due to the electrical resistance of the material (called Joule effect).

A boil is used to transfer energy into the piece to be heated using an alternating electromagnetic field in its mirror image.

The electric current flows through the coil and generates the electromagnetic field that is capable of producing the electric field that is capable of producing the electric current in the piece.

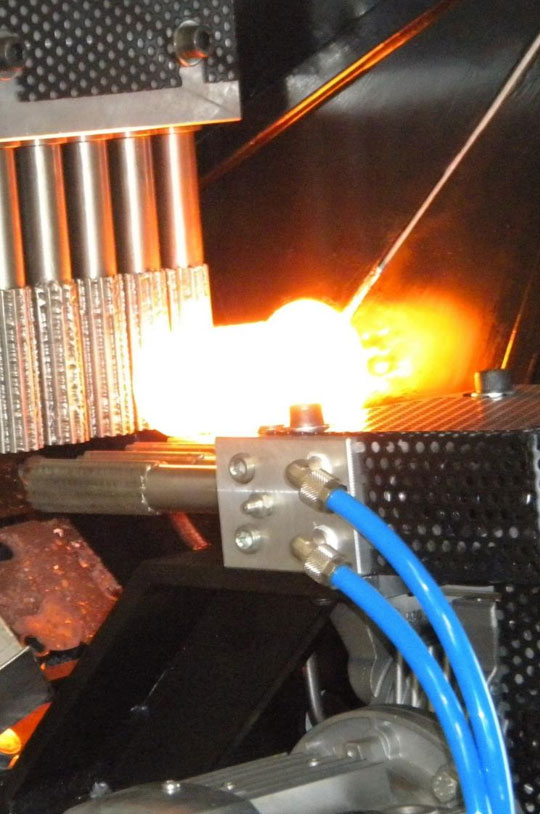

The coil, most often called heating coil, defines the electromagnetic field and therefore the effectiveness and the efficiency of heating.

The heating coils for induction heating can have very different shapes and complexities: from a simple single-coil or solenoid heating coil ( which consists of a copper tube shaped around a spindle) to precision heating coils machined from semi-finished copper and brazed together.

WHY CHOOSE INDUCTION HEATING?

ADVANTAGES

- Presence of electricity only with adequate control systems and high security.

- Flameless. The highest detail in temperature is the heating material as the process is based on the self-heating of steel due to induced currents.

- Very low presence of oxidation of the material, moreover with the possibility of increasing its quality by blowing simple nitrogen into the heating inductor

- Therefore the absence of slag ensuring quality of the heated material directed to the subsequent processing and longer duration of the moulds.

- Lack of need for pre-accensions with the start of the production in a very short time.

- Easy maintenance with system switching on and off of the system in a few moments.

- Limited machine downtime.

- Ability to regulate the heating temperature of the pieces quickly and directly.

- Short heating times, every single piece remains in heating for a short time (the sufficient time for the core of the material to be in temperature) avoiding oxidation and decarburization. Compact systems with limited space requirements.

- External systems limited to the water cooling system and the source of electricity.

DISADVANTAGES

- Complexity of the machine with internal electronic technology.

- Need of adequate electrical distribution system.

- Risk of melting of the material if serious errors are made in the heating parameter settings or in conditions of forced manual commands by the operator.

- Lower yields on non-homogeneous or complex figures. The greatest yields are obtained on bars or pieces of a regular, square or round shape to better match the heating inductor.

CONCLUSIONS

The many advantages of using an inductor heater, especially in the field of hot forging, gardening, heating coating tubes, casting of precious metals, have led the entire market for years now to prefer this type of technology for the thermal raising of workpieces.

Applications

The areas of application of metal induction heating are numerous, multiple and disparate.

The great dynamism and creativity make INDUCPOWER a versatile company present in all sectors of induction heating, and in particular:

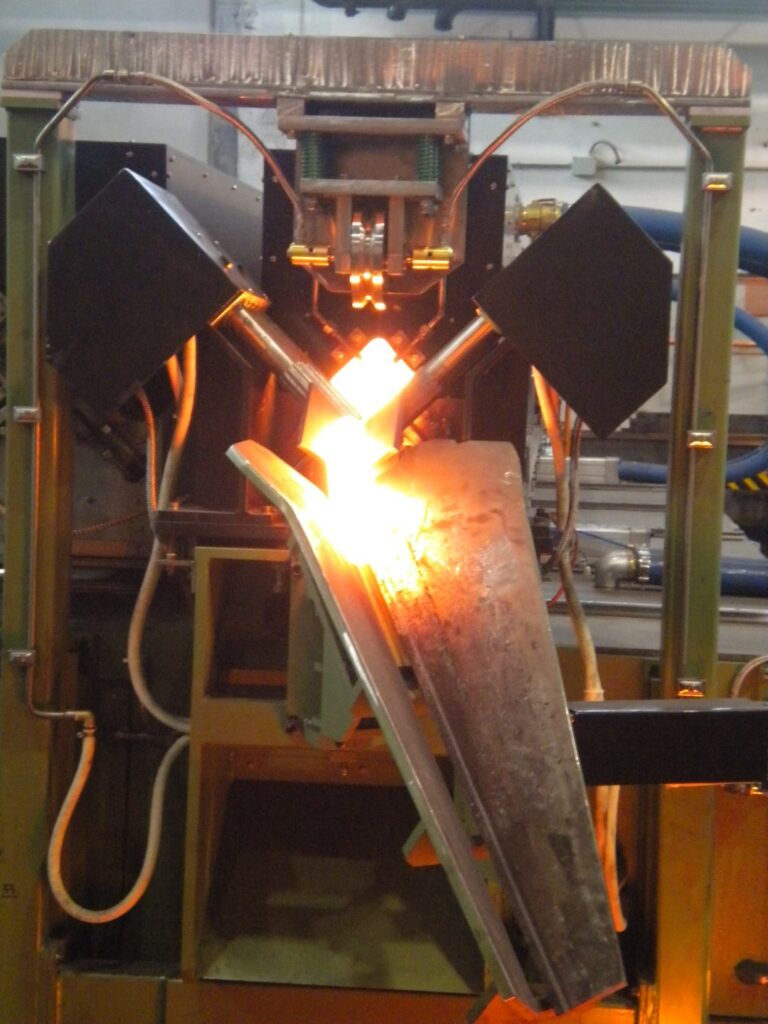

- Total and partial heating for hot forging or forging of ferrous and non-ferrous materials

- Heating for subsequent extrusion of metals

- Surface and deep hardening of metals, tempering

- Annealing and stress relieving, localised or in-line of wires and tubes

- Melting of common and precious metals

- Hot shrink-fitting, hot shrink-scaling, hot and semi-hot deformation, automotive perimeter heating and localised heating

- Heating for pipe coating

- Heating for melting or vacuum sintering

- Brazing of copper, steel and hard metals with alloy addition

- Tempering by elimination of superficial hardening

- Tinning, heating by evaporation or increase in fluids temperature